BGA-TF specialty no-clean tacky flux for BGA soldering (ROL0)

Adjusted solids content for BGA, QFN, LGA assembly

STIRRI®

SKU:TF-SGA-A05-K

In stock

Couldn't load pickup availability

STIRRI-BGA-TF specialty no-clean universal tacky flux (ROL0) provides reliable soldering of BGA components, featuring BGA-balanced viscosity with an increased amount of solids. Specifically designed for BGA purposes, it addresses BGA slumping issues. However, despite its primary focus on BGAs, the flux can adequately perform also for any other soldering task, including leaded or unleaded hand-soldering with hot-air or machine soldering.

BGA solder sphere slumping is a defect that occurs during the reflow soldering process, where the solder spheres deform and spread out, resulting in poor solder joint formation. This can lead to various issues, including:

- Poor electrical connection: The spread-out solder spheres may not adequately contact the BGA pads, leading to increased resistance and potential electrical failures.

- Mechanical weakness: The reduced solder volume can weaken the joint, making it more susceptible to mechanical stress and vibration.

- Thermal fatigue: The non-ideal solder joint shape can accelerate thermal fatigue, reducing the component's lifespan.

Several factors can contribute to BGA solder sphere slumping:

- Excessive reflow temperature: High temperatures can cause the solder spheres to melt excessively, leading to deformation.

- Insufficient reflow time: If the solder spheres do not have enough time to solidify properly, they can slump as they cool.

- Poor solder flux/paste quality: Substandard solder paste can have inadequate viscosity, allowing the solder spheres to spread.

- Component placement accuracy: Inaccurate component placement can lead to uneven solder distribution and increased slumping.

- PCB design issues: Poor PCB design, such as inadequate thermal vias or insufficient copper thickness, can contribute to slumping.

To prevent BGA solder sphere slumping, it is essential to:

- Optimize the reflow profile: Carefully control the temperature and time parameters to ensure proper solder melting and solidification.

- Use high-quality solder flux/paste: Select a solder paste with appropriate viscosity and thermal properties.

- Ensure accurate component placement: Employ precise placement equipment and techniques to minimize misalignment.

- Design for manufacturability: Consider factors like thermal dissipation, component placement density, and solder joint geometry during PCB design.

- Implement quality control measures: Regularly inspect solder joints for defects and take corrective actions as needed.

By addressing these factors, manufacturers can minimize BGA solder sphere slumping and improve the reliability of their electronic products.

While BGA-TF has low activity and is a safe bet, for higher activity BGA/rework consider Hydra-MA-TF resin-based synthetic REM1 tacky flux. Made for the OEM manufacturing, Hydra-MA-TF may surpass BGA-TF in assembly line industrial-grade performance.

Product Description

Product Description

Suitability

Suitability

Adjusted solids content for BGA, QFN, LGA assembly

Designation

Designation

Viscosity

Viscosity

mPa/s (Malcom @ 10 RPM/25ºC (x 10³mPa/s))

Disclaimer

Disclaimer

The information contained herein is based on technical data that we believe to be reliable and is intended for use by persons having relevant skills at their own risk. Consumers should make their own tests to determine the suitability of each product for their particular process and take safety measures. Manufacturer/resellers assume no liability for results obtained or damages incurred through the application of the data presented.

Cleaning "No-Clean"

Cleaning "No-Clean"

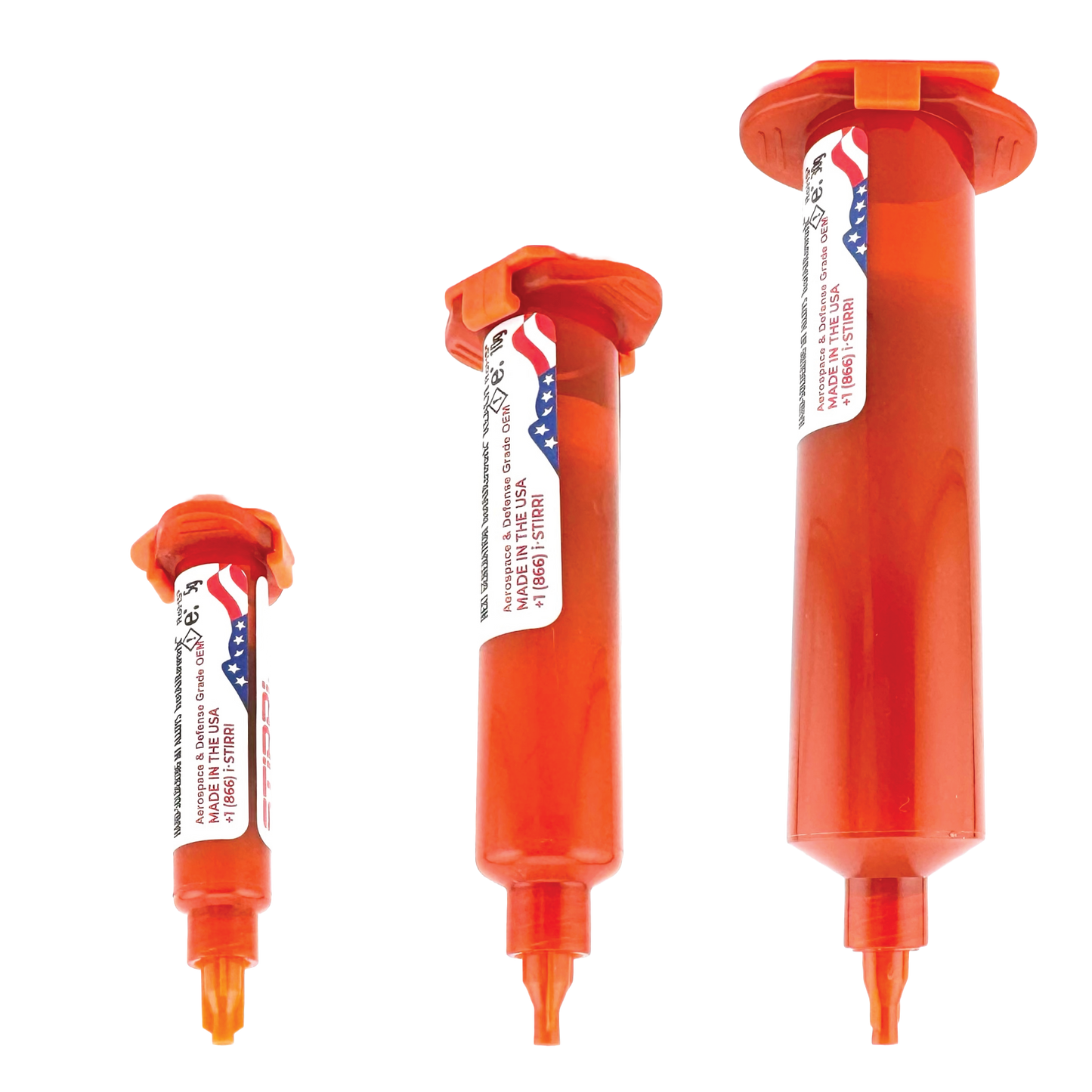

Dispensing Kit

Dispensing Kit

This product does not include any Dispensing Kit - a separate purchase!

Dispensing Kit is an add-on for manual dispensing, used to create a pressure with a plunger similarly to a medical syringe.

Air syringes intended for pneumatic dispensing machines use a piston stopper instead of a plunger. Do not remove the piston as it delivers the best seal preventing contact with air!

Compliance

Compliance

This material is certified REACH-compliant - does not use any raw materials from the REACH restricted list of substances of high concern.

Share

RFQ - Request For Quotation

You are in good hands!

Made in the USA to the applicable industry standards 100% customer satisfaction guaranteed!

Liquid-proof the assembly with Nano-Coating - dries in less than 8 seconds

STIRRI HydraCoat™ is a liquid repellent making PCB liquid proof, instantly improving assembly value!

With an impressive droplet contact angle of over 113º, this nonconducting solution creates an invisible hydrophobic shield repelling weather, humidity, moisture - coated PCB continues to function even when fully submerged!

Broadly suited for consumer devices, automotive circuits, urban and landscaping lightning, LED, medical or electronic devices, marine, boating and yachting industries.

Dry to touch in less than 8 seconds, self cures in 24 hrs or 10 min in 60ºC chamber.

STIRRI's Conformal nano-coating ensures end-customer satisfaction while virtually eliminating assembly claims due to environmental or consumer liquid damages.